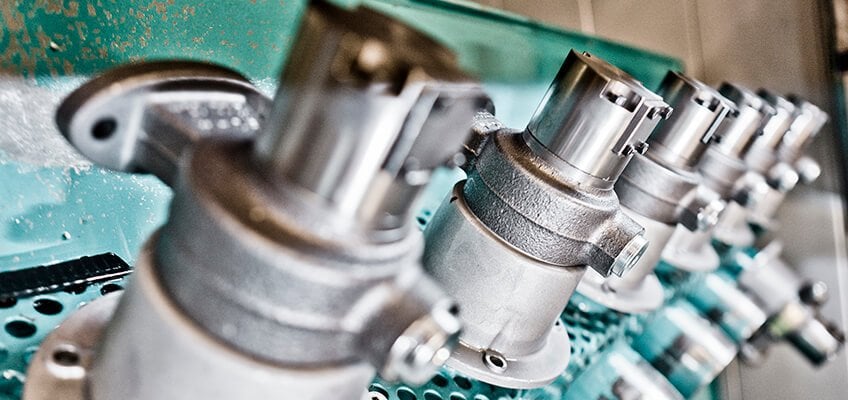

products - CJC® oil filtration systems

The global leader in offline oil filtration - C.C.JENSEN - has 70 years of experience in manufacturing oil filtration and purification systems. We design and manufacture CJC® Offline Oil Filters and CJC® Online Condition Monitoring solutions for all kinds of production systems within the industry, marine, mining, power and wind segments. Our oil filtration systems are designed to reduce oil and energy consumption through oil purification. Our oil filters ensure the oil is documented clean and dry in your production equipment, whether it contains 10 litres or 200,000 litres of oil or even more. Our systems provide continuous oil filtration 24/7/365 and are not system critical, so that, for example, machinery does not need to be shut down when changing CJC® Filter Inserts.

Reduce machine downtime with oil purification

CJC® Oil Filters continuously remove particles, water, acidity and oil degradation products from all kinds of oils and fluids, including hydraulic oil, lube oil, gear oil, engine lube oil, marine diesel oil (MDO), marine gas oil (MGO), heat transfer oil, honing oil, quenching oil, rolling oil, washing oil, synthetic gear oil, turbine lubrication oil, phosphate ester oil, on-load tap changer oil, water-glycol and even biodegradable oil and environmentally acceptable lubricants (EAL). This reduces oil and energy consumption and machine downtime.

Your benefits with CJC® Offline Oil Filtration systems:

- Reduced wear and failure of components

- Increased oil and component lifetime

- Longer lifetime of in-line filters

- Fewer oil changes

- Reduced power consumption

- Fewer unplanned breakdowns

- Increased availability

- Reduced oil maintenance costs

- Lower environmental impact

Significant cost savings with oil filtration

By investing in our oil filtration systems, you will achieve the lowest cost per kilo of dirt removed and significant cost savings, with both short- and long-term benefits. For example, your in-line oil filters and components will have longer lifetimes. Your machinery will need less frequent oil changes and repairs. You will avoid many of the oil-related failures and breakdowns caused by contaminated oil. Our CJC® Oil Filters are recognised around the world as being highly efficient.

Filter Inserts

Dirt and water holding capacity up to 4 L / per insert, 3 µm absolute

Fine Filters

Removal of particles and oil degradation products, and absorption of water

Filter Separators

Removal / separation of water, removal of particles and oil degradation products

Gear Flushing Unit

Flushing and Offline Oil Filtration for Wind Turbine Gearboxes - in one system

Varnish Removal Unit

Removal of contaminants from oil in Gas & Steam Turbines

Heavy Duty Filters

For mobile mining equipment working under severe conditions

Desorbers

Removal of large amounts of water from emulsified oils

Monitoring Equipment

Oil Contamination Monitoring OCM with particle counter

Ion Exchange Filter

Removing acidity, reducing TAN, improving resistivity and surface tension

Oil Absorb Systems

Removal of oil from bilge water, polishing systems

Oil Absorb PreConditioners

Conditioning of bilge water

Accessories

For use in offline oil filtration systems