A filter insert

Specially designed for filtration of small volume hydraulic and lubricating oils

The CJC® A Filter Inserts are designed with fine filtration, high dirt holding capacity and low operation cost in mind, resulting in lowest cost for removing one kilo of contamination from oil. The A Filter Inserts remove all four contamination types in one and the same process: particles, water, varnish, and acidity.

Due to the relatively high pressure loss compared to other CJC® Filter Inserts, the A Filter Insert is primarily used for low viscosity or warm oils.

For decades, the A Filter Insert has proven its value in real-life applications in thousands of oil systems. The A Filter Insert is used in CJC® Fine Filters HDU series.

Used for maintenance of below applications:

- Small hydraulic systems

- Small engines e.g. generator sets

- Small lubricating oil systems

Contamination Capacities

Based on field experience, we have observed that the total Dirt Holding Capacity (DHC) is dependent on shape and density of particles and other variables within an oil system.

When saturated, the total weight of accumulated contamination depends on the application, the combination of contaminants, as well as the density of the captured contamination.

Your benefits with CJC®

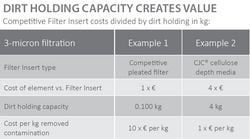

CJC® Filter Inserts have the highest dirt holding capacity on the market due to special cellulose-based material. Furthermore, the unique construction of the bonded discs, creates a large filtration area resulting in reduced costs of ownership. The CJC® Filter Inserts are a modular design, which allows them to fit any applications and requirements.

- The CJC® Filter Insert features:

- Depth media of moulded cellulose

- Highest Contamination Capacities (DHC)

- 100% natural cellulose fibres from sustainable resources;

no plastic, no metal, no chemical

- Removal of contaminants, 4-in-1:

- Particles:

Lifetime of both oil and component are increased considerably. - Oil degradation products:

Avoid sticking valves, lacquering, and varnish on metal surfaces. - Water:

Reduce the risk of micro-pitting, bacterial growth, sludge etc. - Acidity/TAN:

Reduce oil ageing and wear on equipment.

- Particles:

- OEM requirements

Experience and application knowledge of C.C.JENSEN ensure that CJC® solutions can meet specifications from OEMs on oil cleanliness.

How to ensure Clean & Dry oil

Remember to change CJC® Filter Inserts according to pressure gauge or at least once a year in order to ensure clean & dry oil! - Click here to learn how to replace a CJC® Filter Insert.