Learn how to achieve significant savings by optimising your oil filtration solutions

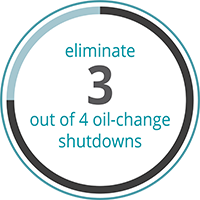

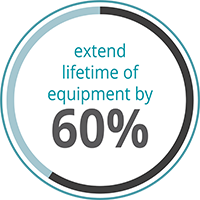

You can eliminate 3 out of 4 oil change shutdowns, extend component lifetime and reduce oil consumption by up to 75%

When the market is tough, workers across the mine pull together to find new ways to cut costs and extend the life of their equipment. The same is true in the wind-turbine industry, where permanently low commodity prices drive a serious need for equipment uptime. In that industry, they rely on CJC® Offline Oil Filtration systems to avoid turbine shutdowns and downtime. CJC® serves 60% of the global wind turbine market.

Today more and more manufacturers of mining equipment have adopted this practice and installed CJC® Oil Filtration solutions right from the factory. Mining operations using CJC® have eliminated 3 out of 4 oil changes, extend component lifetime by 60% and reduced oil consumption by up to 75%. The same can be achieved in your mine.

In-line filtration alone is often not enough!

In-line filtration protects your oil system against larger particles, but CJC® Offline Oil Filters maintain your oil continuously clean and dry free of also small and harmful particles using a constant pressure and flow. This is the best way to extend lifetime of components and oil, minimizing breakdowns. You get 24/7 oil filtration, even during system shutdown and with the market’s highest dirt holding capacity.

See what these CJC® customers have achieved

BHP Billiton reduces downtime by 87%

A CJC® Oil Filter on BHP’s primary crusher eliminated 3 out of 4 oil changes, avoiding shutdown costs of $10,600 per hour per shutdown, saving $479,600 annually

- Read more about BHP Billiton