gas turbine - liquid fuel tank

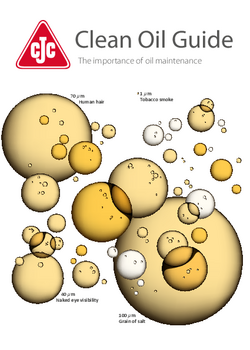

Liquid fuel tanks for diesel powered gas turbines are designed for the particular site in terms of characteristics and volume. Whether the tank is a receiving or service tank, they all face the same problem with diesel being contaminated by particles and water when it is delivered, and deterioration of the diesel quality starting after only a few weeks in tanks. Diesel holding capacity is large and keeping it on ISO 16/14/11, and free from water will improve performance and lifetime of the turbine.

Challenge

The liquid fuel goes through a lot of steps from the refinery to the storage tanks, and along the way, particle content increases, water content increases, and traces from sludge and bacteria can be found in the diesel. If the diesel is not kept clean and dry, and free from sodium and potassium you risk very expensive repairs or replacements, down-time and lower output. Dirty liquid fuel will also lead to premature overhaul and even turbine trips e.g. due to rotational imbalances when the fuel nozzles are not supplying an equal amount of fuel.

Benefits, installing CJC® Oil Filters

- Avoid shut-downs due to failing or tripping gas turbines

- Extend lifetime of turbines and turbine components, e.g. blades , nozzles etc

- Reduce spare parts consumption by up to 60%

- Protect your investment

- Reduce risk of unplanned breakdowns, repairs and maintenance and get piece of mind

There is a direct correlation between diesel fuel cleanliness, equipment uptime and operating costs. When you install a CJC® Oil Filtration solution on your liquid fuel tank, you get the oil filter with the highest dirt capacity suitable for the normal service intervals, so that you do not need to service the filter untimely. Technically, CJC® is known for removing sodium and potassium, and for keeping the fuel clean and dry which has been documented over many years and in many installations. CJC® Oil Filtration solutions are installed in many power plants worldwide, and when you choose CJC® Oil Filters, you ensure a long lifetime of the gas turbine. And you can even monitor from remote the condition of your diesel using the Oil Contamination Monitor (OCM).

Your solutions

For gas turbine liquid fuel tanks the following CJC® system solutions apply:

- Fine Filter, HDU 27/54

- Fine Filter, HDU 27/108

- Filter Separator, PTU3 Multistay

- Oil Contamination Monitor, OCM15

The CJC® System solutions fit all liquid fuel storage tanks regardless of oil volume, and we can deliver globally where required. In close co-operation with technical organizations, we help select the most fitting solution depending on system type and conditions in the environment.