Avoid contaminated oil

Avoid dirty oil - contaminated oil causes approximately 80% of all oil related system failures!

Contaminated oil is a leading cause of oil system failures, accounting for approximately 80% of all oil related failures. By avoiding dirty oil and its related problems, equipment reliability and lifetime can be significantly improved.

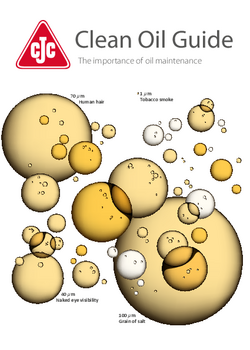

Contaminated oil occurs when insoluble materials such as metals, dust particles, sand, rubber, and varnish accumulate in the oil, resulting in dirty oil. The tiniest particles, known as silt, resin, or oxidation/varnish deposits (usually below 2 µm), are often the cause of equipment defects.

These contaminants can have a detrimental impact on the reliability and lifespan of your equipment.

Almost 100% of contaminated oil and associated problems can be prevented. C.C.JENSEN has extensive expertise in oil maintenance, and have developed specialized systems to effectively remove the following contaminants:

- Particles: Our advanced systems are designed to efficiently remove dirt-particles of various sizes, ensuring clean and particle-free oil circulation within your equipment.

- Free water: By addressing free water, we mitigate the risks of corrosion, oxidation, and reduced lubrication effectiveness. Our solutions prevent water and moisture-related complications that can harm your equipment.

- Dissolved water: Our techniques address dissolved water, minimizing its presence in the oil and maintaining the optimal balance to avoid detrimental effects on your equipment.

- Oil Degradation: We combat oil degradation and varnish formation, which can occur due to factors such as heat, oxidation, and chemical reactions with oil contaminants e.g. cupper and water. Our solutions help preserve the quality, properties, and performance of the oil, extending the life of your equipment.

- Oxygen / air: By minimizing the presence of oxygen and air in the oil, we reduce the likelihood of system break-down or reduced operating precision. This helps maintain the oil's stability and protects critical components. We offer solutions to remove oxygen and air from the system.

- Acidity: Our specialized methods neutralize acidity formation within the oil by keeping contaminants and moisture levels low.

- Oil in water: We employ effective techniques to remove oil from water, ensuring that your bilge water remains as low as 5 mg/L (ppm).

With our comprehensive oil maintenance strategies, you can proactively safeguard your equipment, enhancing its reliability and extending its operational life. By choosing our trusted solutions, you eliminate the risks associated with dirty oil and its consequences.

Experience smoother operations, reduced maintenance costs, and optimized performance by partnering with C.C.JENSEN.

Avoid oil related problems, use CJC® Products...