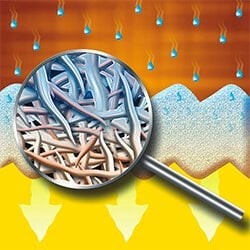

dissolved water

In some applications e.g. marine, steel and paper industries, ingress of water is a major problem, and removal of water in oil can become a necessity. In order to avoid excessive amount of free water settling out in bearings and gears, special oils with the ability to hold water suspended, have been developed e.g. oil for paper machines.

Water can be dissolved in oil in two ways:

- Suspended and tied up until the oil’s saturation point (typically between 200 – 600 ppm water, depending on oil type)

- Emulsions – colloidal suspended water in levels above the saturation point

For optimal protection of machine components the water content should not exceed 30% of the saturation point. Emulsions of water/oil occur mainly due to shear forces in machinery e.g. in pumps, gears and valves.

The problems caused by emulsified water are similar to those of free water i.e. corrosion, cavitation, micro-pitting and oil degradation. Degraded oil only separates water poorly, because the oxidation products (acid, aldehydes, ketones) are polar and encapsulate water droplets, hindering merging of drops and separation by gravitation.

CJC® Filter Separators and CJC® Desorbers remove water in oil. Desorbers are used for oil types which create emulsions, while Filter Separators are used for oil types which will let water separate out by gravity.

Water in oil - solution:

For effective removal of water in oil, use CJC® Filter Separators for eg.:

- Thrusters

- Steam Turbines etc.

For effective removal of larger amounts of water in oil use CJC® Desorbers for eg.:

- Paper Machines

- Steel Industries etc.

Learn how other customers benefit with CJC® – Click to download Customer Cases.

- Alstom Transformer 60 MVA_Power Supply_Transformer Oil_SNCF for RFF_French Railway_ASIN5143

- Alu. Injection Moulder_Italpress-Pretransa-Idrapress_Hydr Oil_Ruffini_ASIN5048

- Ball Mill SAG_Main Lube System_Copper Mine_Lube Oil_CMD Chile_ASIN5027

- Bulk Tank_Telemetric Readings_Hydraulic Oil_KLM Equipment_ASIN5066

- Caterpillar Excavator D10R Diesel Eng_Lube Oil_Codelco Chile_ASIN5026

- Cement Mill, Main Gearbox, Gear Oil, Portlandzementwerk Wittekind Hugo Miebach Söhne, ASIN5156

- Chamber Filter-Press_Waste Management_Hydraulic Oil_Germany_ASIN5110

- Container Straddle_Preussag_Hydraulic Oil_Piraeus Port Authorities_ASIN5003

- Cooling Tower Fan Gear_Gear Oil_Major UK Power Plant_ASIN5108

- Diesel Engine_Volvo Penta TAMD 162_Coaster_Lube Oil_MONSUNEN_ASMA7002

- Drilling Machine_Drilltech_Copper Mine_Hydraulic Oil_CMD Chile_ASIN5029

- Gas Turbine_Alstom GT8C_Turbine Oil_Gorzow Power Plant_ASIN5055

- Gas Turbine_Turbomach 7.5 MV_Lube&Hydr Oil_Onda Cogeneracion_ASIN5070

- Generator Transformer_T08-15 MVA-53.9/5kV_De-gassing_Transformer Oil_Haflund Produksjon_ASIN5047

- Heat Treat Furnace_Quench Oil_Automotive Manufacturer_CCIN5164

- Hydr. Syst & Thrusters_Trawler/Fishing Vessel_Hydr. & Gear Oil_RAV_ASMA7019

- Hydr.Syst & FuelTank_Fishing Vessels_Hydr&Diesel Oil_PAUL SENIOR_ASMA7020

- Hydraulic Control_Injection Pump & Exhaust Valves_MAN Engine_Hapag LLoyd_ASMA7029

- Hydraulic System-Traditional_Fishing Vessel_Hydraulic Oil_BRITTA_ASMA7005

- Hydraulic Systems_Return Tank_Submarine_Hydr Oil_BRUINVIS_ASMA7010

- Hydro Turbine_Sulzer_Bevel Gear & Control_Turbine Oil_Ontario Power_ASIN5076

- Liebherr Pontoon Excavator P 995_Hydraulic Oil_Josef Mobius Bau-Aktiengeschellschaft_ASIN5127

- Main Steam Turbines_Turbine Oil_Midtkraft A/S_ASIN5021

- Mitsubishi Lathe Lube System_Roller Bearings_Hydr Oil_Timken Polska_ASIN5054

- Paper Machine_Bowser Lube System_Lube Oil_Norske Canada_ASIN5062

- Paper Machine_PM4 Central Lube Syst_Lube Oil_Norske Skogind_ASIN5014

- Pitch Hydraulic, Wind Turbine, Vestas V90-2MW, Hydraulic Oil, Arise Sweden, Oxhult, ASWI9007

- Plastic Injection Moulder_BILLION_Hydr Oil_Neyr Plastiques_ASIN5073

- Plastic Injection Moulder_BILLION_Hydr Oil_Novaes_CCIN5073

- Plastic Injection Moulder_ENGEL-STORK ST4000-550_Hydr Oil_DPI Dielco_ASIN5046

- Plastic Injection Moulder_PONAR ZYWIEC_Hydraulic Oil_ZMM Maxpol_ASIN5057

- Precision Engineering of Metal Parts_Lube and Cutting Oil_Panalok_ASIN5096

- Quenching Plants_Quench Oil_ASIN5034

- Rotor Gear_Desmi_Waste Water Treatment_Gear Oil_Svendborg Central_ASIN5049

- Sealing Rings for Hydr. Systems_Honing/Lapping Oil_Trelleborg Sealing_ASIN5103

- Ship Unloader Siwertell_Boom Lifter_Hydr. Oil_AES Philippines Masinloc_ASIN5115

- Stainless Steel Wire Manufact_Pleuger_Lube Oil_Inoxfil Barcelona_ASIN5069

- Steam Turbine_GEC Alstom 7.4 MV_Waste Inci_Turbine Oil_Sirusa_ASIN5063

- Steam Turbine_Siemens_Turbine Lube Oil_Essent Clauscentrale_ASIN5099

- Steam Turbine_STORK 8.6 MW_Recycling Center_Turbine Lube Oil_AVR_ASIN5043

- Steel/Alu Rolling Machine_Alcoa/Ragsdale_Lube Oil_Ball Packaging_ASIN5008

- Steering Gear_RotaryVane_RollsRoyceTenfjord_HydrOil_DANA SIRENA_ASMA7024

- Thermal Oil Plant_Heat Transfer Oil_Pharmaceutical Prod_Shasun Pharma_ASIN5098

- Transformer Power Plant_Brush_Transformer Oil_Copenhagen Energy_ASIN5020

- Water Turbine_CKD Blansko_Control System_Turbine Control Oil_Niedzica SA_ASIN5071

- Wind Turbine Gearbox, GE 1.5S, Winergy, Planetary & Parallel, Gear Oil, Shenhua Guohua, Dongtai China, ASWI9003

- Wind Turbine Gearbox, Sinovel FL 1500, DHI-DCW, Gear Oil, Shina Datang Corporation Renewable, ASWI9004

- Wind Turbine Gearbox,3-stage-planetary/helical, Gear Oil, Flender AG, ASWI9000UK