desorber D40

Water in oil leads to reduced viscosity, reduced filterability, reduced lubricity, formation of rust, bacterial growth and increased oil degradation - all factors that lead to reduced lifetime of both components and oil.

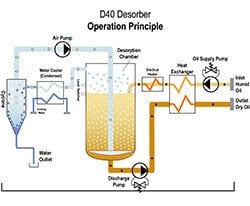

CJC® Desorbers D40 is designed to remove water from oil through the patented desorption principle. The desorption process is based on the principle that heated air can effectively hold large quantities of water. In the Desorber, oil preheated to 60-80°C (defined by the customer) is met by a counter flow of cold, dry air. The air, heated very quickly by the hot oil, will absorb any water present until saturation is reached. The Desorber can dry the oil down to a water content of < 200 ppm, removing 8 L of water per hour, depending on the oil type.

The advantage of the CJC® Desorbers D40 is that it is unaffected by viscosity and additive packages. The Desorber treats mineral oils as well as synthetic fluids, and even breaks stable emulsions. The Desorber maintains system water content to very low levels.

Features:

- Removes water even from emulsified oil

- Extends the lifetime of both oil and system

- Prevents uncontrolled break downs and reduces maintenance costs

- Easy to connect and operate