varnish removal-indsats, VRI 27/27

Optimal fjernelse af oxidationsrester, harpiks, fernis og slam

FRA GAS- OG DAMPTURBINER

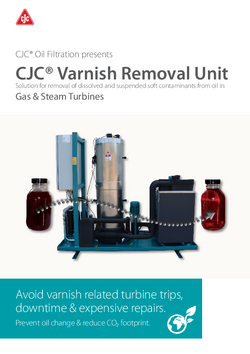

CJC® Varnish Removal-indsats, VRi 27/27, anvendes i CJC® Varnish Removal Unit, VRU, og er specialudviklet til effektiv filtrering/fjernelse af opløselige oxidationsrester i mineralsk og syntetisk baseret:

- hydraulikolie

- turbinesmøreolie

FILTRERINGSEVNE

Nedbrydningsrester

Oxideringsrester, harpiks, fernis og slam tilbageholdes af det specialudviklede cellulosemateriale, som tilbageholder omkring 2 kg pr filterindsats.

Det er dokumenteret, at VRi 27/27 ikke påvirker additiverne så som anti-oxidanter i olien (aminer/fenoler).

KOMPONENT

CJC® Varnish Removal indsats, VRi 27/27, består af sammensatte dobbeltskiver fremstillet af en celluloseblanding, som er nøje udvalgt af flere forskellige typer cellulosefibre for specifikt at opnå effektivt fjernelse af olieopløselige oxidationsrester.

Denne indsatstype fungerer kun, hvis den anvendes sammen med CJC® Varnish Removal Unit, VRU. Det specielle flow, recirkulation og køling, som er karakteristisk for CJC® VRU, sikrer, at olieopløselige oxidationsrester krystalliseres og fjernes effektivt.

IDENTIFIKATION

Bestil Varnish Removal indsats VRi ved hjælp af:

Varenr.:

1 x VRi 27/27: PA5601370

Klik her for at få mere at vide om udskiftning af en filterindsats.

Documented cases have shown the removal of 4 kg (4,000 g)/8 lb of solid contaminants and oil degradation products per filter insert with one VRU Filter Insert change (4 x VRi 27/27 16 kg/32 lb). Single-pass efficiency for varnish removal and MPC reduction of up to 99 percent. An Ultra-Centrifuge test can also be used to detect varnish.

Your benefits with CJC®

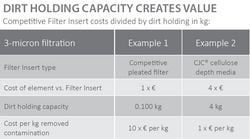

CJC® Filter Inserts have the highest dirt holding capacity on the market due to special cellulose-based material. Furthermore, the unique construction of the bonded discs, creates a large filtration area resulting in reduced costs of ownership. The CJC® Filter Inserts are a modular design, which allows them to fit any applications and requirements.

- The CJC® Filter Insert features:

- Depth media of moulded cellulose

- Highest Contamination Capacities (DHC)

- 100% natural cellulose fibres from sustainable resources;

no plastic, no metal, no chemical

- Removal of contaminants, 4-in-1:

- Particles:

Lifetime of both oil and component are increased considerably. - Oil degradation products:

Avoid sticking valves, lacquering, and varnish on metal surfaces. - Water:

Reduce the risk of micro-pitting, bacterial growth, sludge etc. - Acidity/TAN:

Reduce oil ageing and wear on equipment.

- Particles:

- OEM requirements

Experience and application knowledge of C.C.JENSEN ensure that CJC® solutions can meet specifications from OEMs on oil cleanliness.

How to ensure Clean & Dry oil

Remember to change CJC® Filter Inserts according to pressure gauge or at least once a year in order to ensure clean & dry oil! - Click here to learn how to replace a CJC® Filter Insert.

Lær, hvordan andre kunder har fordel af CJC® - Klik for at downloade

Kunde cases på engelsk:

- ALSTOM-Gas-Turbine-GT8C2_Turbine-Oil, Combined-Heat-and-Power-Plant_ASIN5146

- Gas & Steam Turbine GE 109FA, Lube & Hydraulic Oil, Combined Cycle Single Shaft_CCPO6050

- Gas Turbine GE40MW, Lube Oil_Cogeneration Plant_CCPO6052

- Gas Turbine, GE 6FA+e, Bearing, Load Gear & Control, Turbine Oil, Rusal Aughinish Alumina, Irland, ASPO6047UK

- Gas Turbine_2xGE 84 MW_CCCP Power Plant_Turbine Oil_Energyworks Cartagena Iberdrola_ASIN5132

- Gas Turbine_GE 7FA-300 MW_CCGT Power Plant_Turbine Oil_Combined-Cycle Generation USA_ASIN5133

- Gas Turbine_GE-LM6000_Generator Bearings & Gearbox_Turbine Oil_Energyworks Valladolid_ASIN5141

- Power Plant USA_Lube & Control Oil, Combined Cycle-Natural Gas Turbine, GE7FA_ASPO6048

- Urban Waste Management Plant_Steam Turbine, Lube Oil, Siemens SST-400,65 MW_ASPO6051